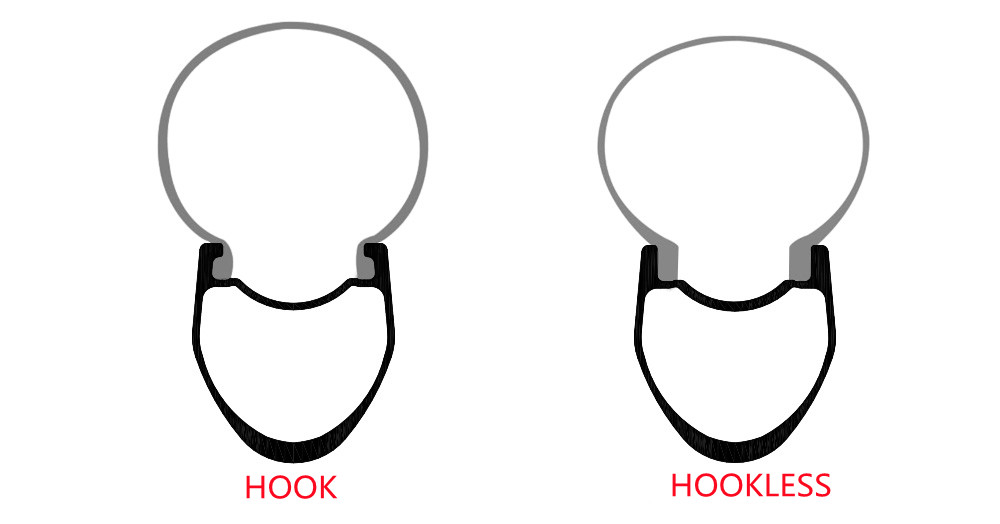

Bead Hook VS Hookless Rims

Hookless rims have been the mainstream in MTB rims for several years.

With the fast increasing demand for gravel bikes, the gravel rims and disc brake road rims are becoming wider and wider.

Some people are considering if they should go for hookless for gravel rims.

Most traditional road rims are designed with hooked bead.

The main function of "hook" is that it helps to hold tire on the rim in extreme condition (especially when tires are in high pressure), preventing it from blowoff.

With the help of "hook", hooked tires are able to be inflated to higher tire pressure.

The max tire pressure limit for our hooked gravel carbon rim (DX33, DX44, DX55,) is 90psi, while max is 60psi for our hookless gravel carbon rim (DX33, DX44).

Why we make hookless rims?

1) Hookless rims are relatively easier to produce. (do not need 3-piece mould to shape the "hook").

2) Better strength and durability.

While making lay-up for hookless rims, the carbon pre-preg is complete from rim channel to both sidewalls. (no need to cut on sidewall so as to create the "hook").

Thus, the sidewalls of hookless rims are thicker and stronger, providing better impact resistance.

3) Better tire/rim engagement.

As hooks are removed from inner side of rim sidewalls, there is wider stance for the tire. So tire will not be squeezed in bead as it was, which makes it less "light bulb effect".

Thus, the tire/rim engagement is more stable, more difficult to be blown out under strong impact.

4) More suitable for tubeless tire.

Almost all tubeless ready rims are designed with bead lock, which serves similar function as bead hook.

So, when using tubeless tire on the rim, the rim "hook" becomes unnecessary.

This is the key reason why most MTB carbon rims are made with hookless. (tubeless tire is standard equipped for MTB rim).

We forecast that hookless will be the mainstream for gravel rims in the near future, just as it had happened on MTB rims.